Getting Her Ship Shape

We bought Latitude in 2018 but the real work started in 2021 during the Covid yard period. At that point we started in on some of the big systems: new standing rigging, North 3Di main and genoa, B&G electronics, new water pumps and a brand new 630 amp hour lithium phosphate battery bank.

At the time, that felt like enough.

Then came the Spring, Summer and Fall of 2025, when Latitude underwent a really major refit. From bow to stern, no system was left untouched.

Above Deck: new downwind double furling tradewind sails and staysail, totally new running rigging, Reckmann headsail furler to Germany for re-build, new windlass, removed, stripped and re-sealed and painted forward deck hatches, re-built hydraulic main furler and gooseneck, boom and spin pole sandblasted and re-painted, all new fixtures on the mast, chainplates removed, tested and re-bed, new backstays, backstay hydraulic seals replaced, all winches re-built, new dodger and tender cover, steering pedestal tops replaced, compasses repaired, new high performance DC powered Starlink system and 5G Pepwave backup, whole exterior wet sanded and ceramic coated, deck joints shaved and teak cleaned and treated. post stuff here.

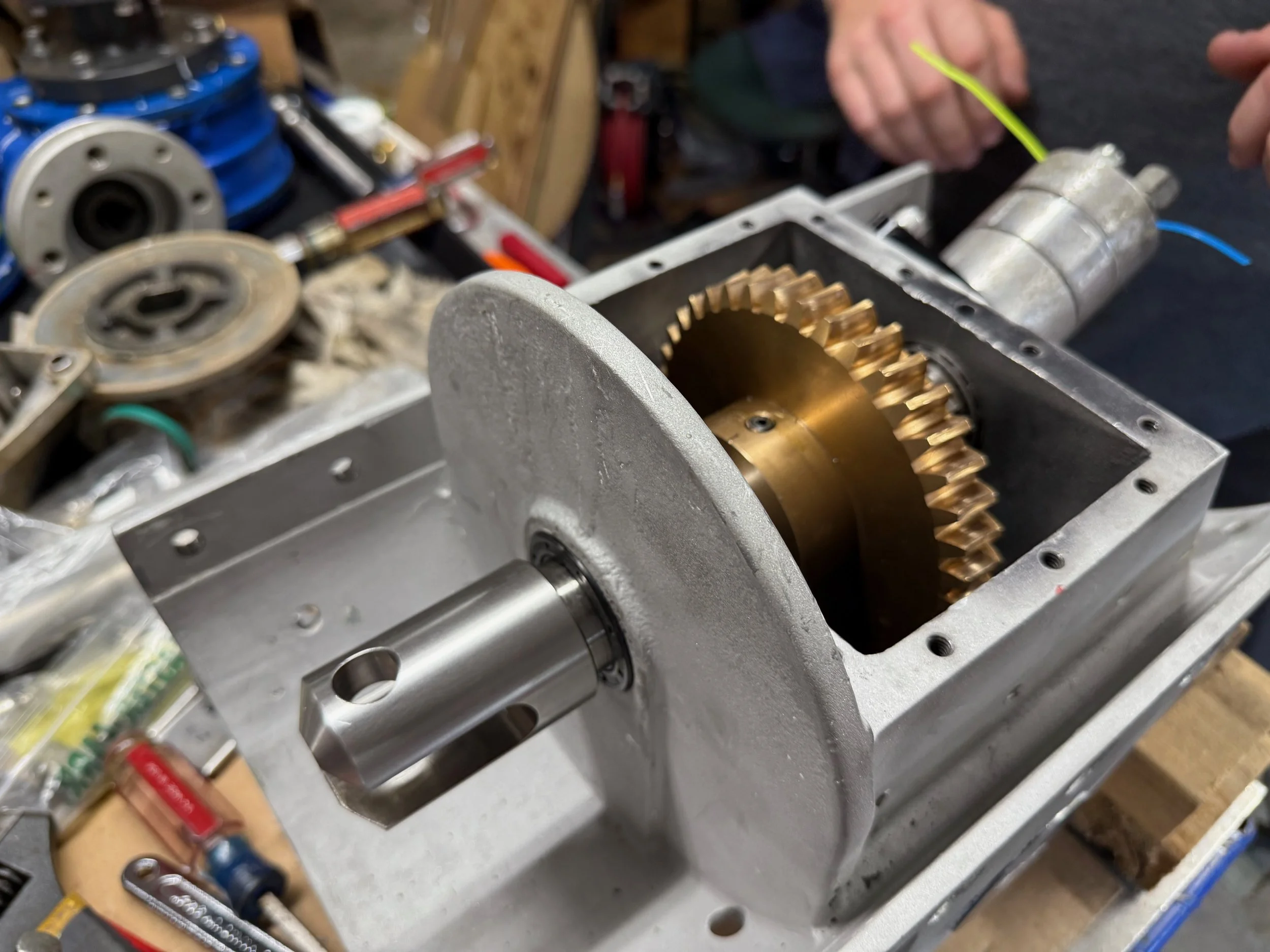

Below Deck: Full service of Lewmar Commander hydraulics, brand new 1800 amp hour Victron lithium phosphate system with new Victron chargers, inverters and controls, brand new Cummins 17.5 kw genset, massive Volvo main engine overhaul and two new 200 amp alternators, replaced refrigeration compressors and keel coolers, watermaker re-build with new pumps and motors, drive line, cutlass bearing and propeller re-built, steering joints and quadrant replaced and re-built, autopilot motor and gearing replaced, lower rudder completely re-built, installed 1,000 pounds lead ballast on port side, fuel polisher, varnish below, sand and 3 coats bottom paint.

Then the really good stuff started. We had been chasing a mystery leak that had been plaguing us since a bad Nor’easter in 2020 did some damage to the rudder while tied up at the dock in Rhode Island. The boat had been hauled and investigated countless times and while we improved the symptoms we had not beaten the cause. In September of 2025 we decided to pull out all the stops, haul her and un-step yet again to get her into a shed and find the problem once and for all.

And we did! Tremendous work by Bristol Marine and Prescott Cronin to finally find the weakness in the skeg, completely excavate to the base beam structure and re-build with untold layers of carbon uni-directional fiber. Latitude now has the driest, strongest skeg in the fleet. Bring it on, Orcas!

(not really)